SERVICES

We are a team of experts, dedicated to supporting project owners, engineers, and contractors from the project’s conceptual phase to detailed design, documentations, and valued engineering. Our commitment extends to practical training and on-site support, ensuring successful project completion. We also offer project specific solutions and optional inspection and maintenance services. Based on our extensive experience in structural strengthening, we guaranteed quality and optimal solutions for your projects. Furthermore, our global partners, who are trained and qualified by us, are empowered to utilize our products worldwide

Advantages at a glance

Professional advice worldwide

Outstanding Swiss quality

A very wide spectrum of applications

International experience

Post-tensioning Systems

CARBOSTRESS

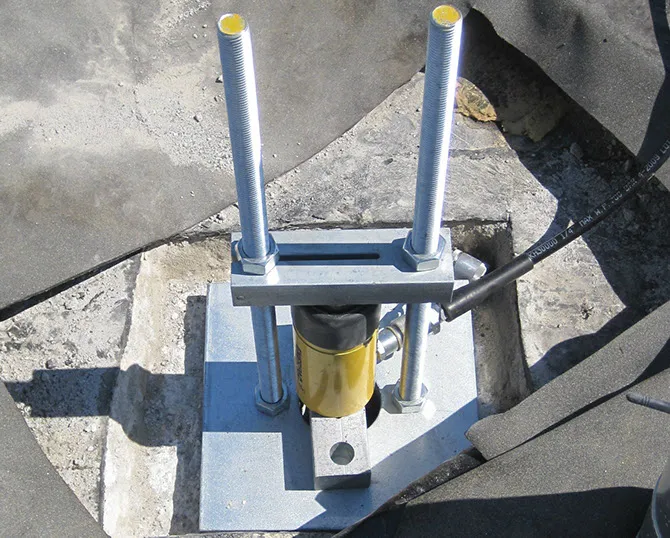

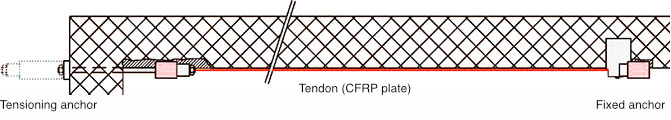

The CarboStress system by StressHead uses external post-tensioning, employing a carbon fiber reinforced polymer (CFRP) tendon and two anchors. These anchors concentrate force at the plate ends, transferring it into the structure.

Our system includes a fixed anchor and a post-tensioning anchor. The fixed anchor secures one tendon end, while the post-tensioning anchor, operated by a hydraulic cylinder, tensions the opposite end. To suit diverse needs, we offer standard and customized anchors.

For enhanced durability, strength, and stiffness, the CFRP tendon can be bonded to the surface or shielded by, for example, a metal cover to prevent mechanical damage.

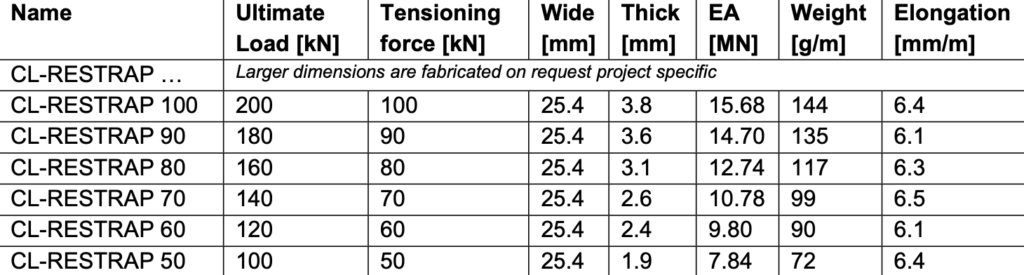

StressHead® CL-RESTRAP is an external post-tensioning system made of carbon fiber reinforced polymer (CFRP) tapes that are wound endlessly into a loop. The use of thin, multilayer tapes allows very small bending radii. The loops can be produced in any length and dimension, have excellent long-term behavior and are easy to assemble by hand due to their feather-light weight.

PRESENTATION

StressHead Ltd regularly conducts roadshows and presentations directly in your office. If you are interested, please contact stresshead@stresshead.ch

We are also happy to arrange individual installation demonstrations for small groups, companies or universities on request. Do not delay, put in your request today.

Installation demonstration locations:

- Schlieren ZH, Reitmenstrasse 7 (CH)